Swiss Type Lathe of the Future, SwissNano from TORNOS

Tornos has a well-established reputation in the field of bar turning for watchmaking, but never before the launch of SwissNano had a manufacturer gone so far ahead in design, ergonomics and integration research into a human-machine interface with a radical focus on efficiency and simplicity.

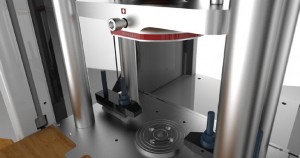

Front, side and back fantastic ergonomic access.

For more than 100 years, Tornos has been manufacturing machines aimed at watchmaking with theirs Swiss Type Lathe, and for around twenty years, the company has been providing NC solutions to meet highly specific watchmaking requirements (Deco 7 & 10, Micro 7/8, Delta 12 and EvoDeco 10, to mention only a few). Therefore, the company knows the market and has had its engineers pull out all the stops to develop a machine whose design stands out resolutely against other products in the market. The aim: to create a new category.

The SwissNano marks a break from the rest of Tornos’ Swiss-Type lathe range in terms of the design and concept of the machine; its aim is an ambitious one. Fully manufactured in Switzerland, it must meet very stringent cost requirements, to be able to counter Japanese and Korean competition, often manufactured in low cost economies. The SwissNano is a demonstration of the performance that the Swiss industry can offer.

Combining all aspects of design

It is well known that design must bring together two aspects: aesthetics, which plays on emotional effect, and the practical aspects that work on both a rational and emotional level. Mr. Renggli, the Tornos Marketing Manager, told us : “We wanted to create a modern automatic turning machine with a 4mm capacity, occupying minimum floor space and with complete 180° access; hence this frontal design, and the integration of a tablet in addition to the conventional control.”

Frontal access: complete freedom of action

Given the space constraints in watchmaking workshops, the machine was developed so as not to require any rear access. If necessary, it can even be placed against a wall. The machining area is protected by a ‘bubble’ and is accessible from all sides. Mr. Renggli, reports: “The setup is user-friendly, not only is everything easily visible, but it also gives us ideal accessibility. We had a very positive experience.”

Foolproof repeatability and precision

The machine’s structure is designed to meet the most demanding needs of the watchmaking industry in terms of precision, repeatability and surface finishes. Thanks to its flexibility, the SwissNano is a competitive solution which effectively meets the needs of the watchmaking industry (amongst others), proving to be the perfect partner for producing any type of small part. The SwissNano may be small, but you will be surprised at its great performance and flexibility.

Setting, monitoring and interaction

The greatest advance may be in terms of communication. SwissNano has a graphic tablet on top. All the basic production data its reported on this interface. At a glance, the operator can access all the data for a specific machine or for the whole fleet. Tablet connectivity provides a number of other services. Therefore, it incorporates an application that allows machine production to be remotely monitored. The SwissNano can communicate with an Android® tablet via a standalone Wi-Fi network, which it’s created between the machine and the tablet. This application allows information on the machine state, the production status and the plan for the work piece currently being created on the machine to be brought up and displayed, along with the service and maintenance instructions, alarms and their troubleshooting methods. All of this is available in a modern, practical interface. What is more, the application is not limited to one machine; it allows an entire workshop or a bank of particular machines to be monitored. The machines and the application are not connected to the Internet or to any network. The machine and the tablet create their own networks automatically. The application recognizes the machines in the workshop and communicates with them via their own network. With concerns over confidentiality.

Born in 2012, Izmade is a sustainable design collective from Turin, Italy that specializes in the field of self-made eco-design furniture and home accessories. Izmade’s products are the result of a marriage between a traditional approach to conceptual design and an artisanal, self-made approach to production. Our design process is centered around environmental sustainability and the enhancement of a material’s original features to create something new and beautiful.

Born in 2012, Izmade is a sustainable design collective from Turin, Italy that specializes in the field of self-made eco-design furniture and home accessories. Izmade’s products are the result of a marriage between a traditional approach to conceptual design and an artisanal, self-made approach to production. Our design process is centered around environmental sustainability and the enhancement of a material’s original features to create something new and beautiful.

Swiss Made is a registered trademark that denotes products that are made in Switzerland. It is such a value for the manufacturer and the consumer that its designation is regulated, protected and controlled by Swiss law.

Swiss Made is a registered trademark that denotes products that are made in Switzerland. It is such a value for the manufacturer and the consumer that its designation is regulated, protected and controlled by Swiss law. 19 new machines

19 new machines

This animal-shaped key ring-sized pocket toolbox is specially designed for a niche sports market and contains every tool necessary for snowboarding, skateboarding and surfing, as well as being appropriate for a wide range of other uses. The inspiration for this compact and multipurpose design was the intended user: a lover of the outdoors, of nature and of the wilderness. The environmental characteristics of this design were therefore critical to its success as a product. It would have been considered irresponsible to design multiple products for this user group using up to 10 times the amount of materials for 10 different tools, including the resultant consumption of energy that this would have required, when an all-in-one tool would suffice.

This animal-shaped key ring-sized pocket toolbox is specially designed for a niche sports market and contains every tool necessary for snowboarding, skateboarding and surfing, as well as being appropriate for a wide range of other uses. The inspiration for this compact and multipurpose design was the intended user: a lover of the outdoors, of nature and of the wilderness. The environmental characteristics of this design were therefore critical to its success as a product. It would have been considered irresponsible to design multiple products for this user group using up to 10 times the amount of materials for 10 different tools, including the resultant consumption of energy that this would have required, when an all-in-one tool would suffice.

Una collezione dalla precisa identità in cui antiche citazioni etniche e pregiate tecniche di lavorazione artigianale si incontrano con “irriverenti” linee asimmetriche, tratti razionali e volumi “trasversali”. È questa la filosofia creativa di Kökler.

Una collezione dalla precisa identità in cui antiche citazioni etniche e pregiate tecniche di lavorazione artigianale si incontrano con “irriverenti” linee asimmetriche, tratti razionali e volumi “trasversali”. È questa la filosofia creativa di Kökler.